How about electric ignition instead of firing pins, flechettes instead of round shot, scopes that self-adjust for elevation, and several other fantastic innovations that may be in the gun shop sooner than you think?

This column, “Far Out Firearms,” appeared in the June 1987 issue of Outdoor Life.

You are living in the most exciting era of firearms history. Ballistic research and gun development now under way are almost certain to revolutionize your shooting within the next 10 years.

One of the great strengths of the American firearms industry is its traditional concepts of design, manufacture, and quality. This is why the quality of American-made guns re mains high while that of many other consumer products steadily declines. But sometimes clinging to traditional concepts has a blinding effect. Let me give you an example.

I predict that gunsmiths will do a flourishing business converting all types of guns to electronic ignition, and that there will be easily installed conversion kits for do-it-yourselfers.

It has long been understood that a gun’s lock time — the time span between the pulling of the trigger and the firing of the cartridge — has quite a bit to do with any shooter’s performance with rifle, pistol, or shotgun. This is because the hold or aim may become faulty after the trigger is pulled but before the bullet or shot charge leaves the muzzle. Accordingly, makers of high-performance guns, especially those used in competition, have gone to considerable lengths to speed up the lock time of their firing mechanisms. This usually includes reducing the weight of the firing pin or hammer so it will accelerate faster when the scar is released, and shortening the distance the striker or firing pin must fall.

To this end, electronically activated trigger-firing pin mechanisms were introduced a few years ago on high-performance pistols and rifles. These electric triggers improved lock time in most cases, and they had the additional advantage of ultra-sensitive trigger pulls. Such innovations are usually hailed as engineering coups. But are they? Isn’t this really nothing more than an effort to deal with a traditional problem in a predictably traditional way? No matter how efficiently modern technology reduces the lock time, the basic problem of hitting the primer with a firing pin still exists.

Electric Ignition

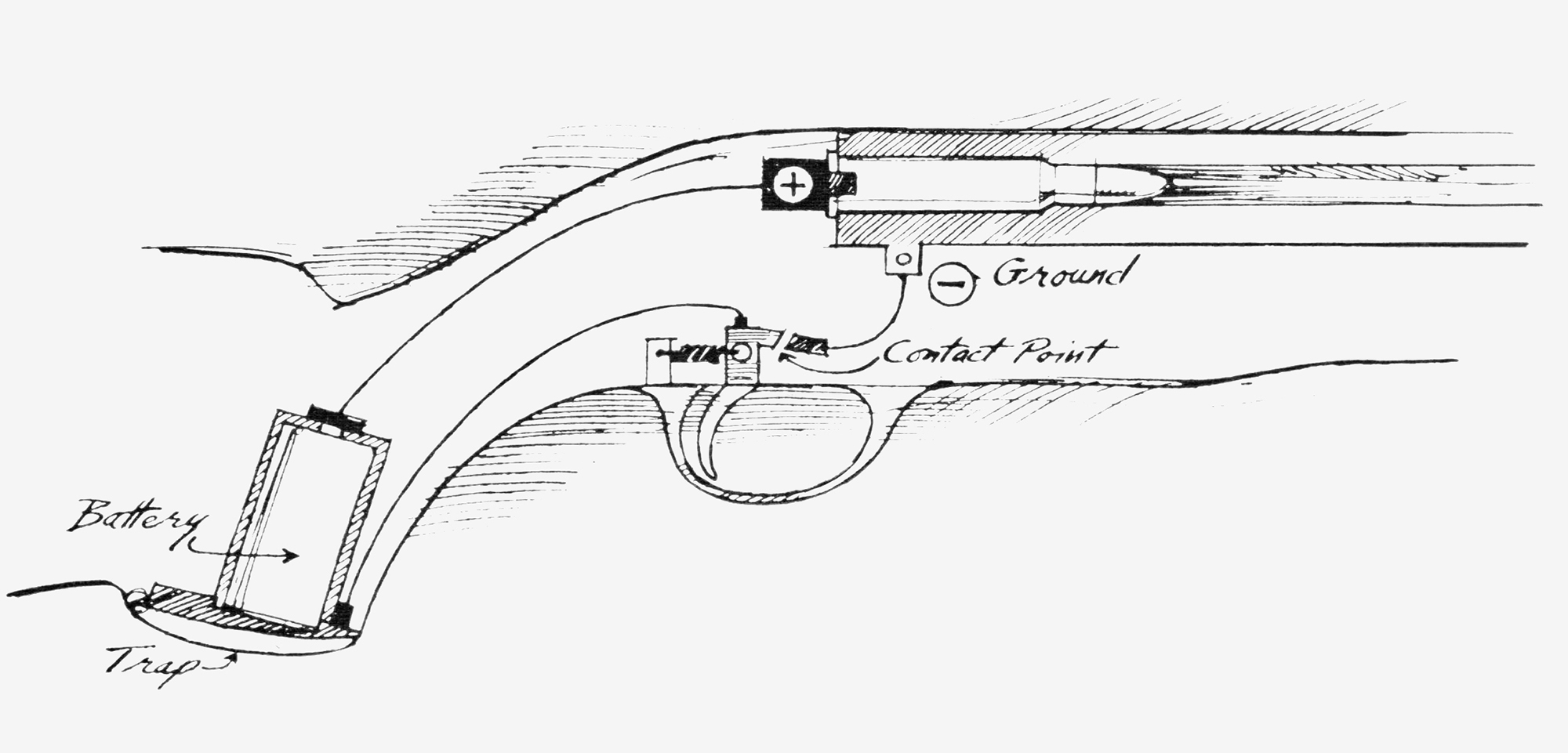

So why not forget the percussion primer altogether and go to a purely electrical system? I’m talking about primers that arc activated by a jolt of electricity, not a mechanical blow. The concept is so simple it boggles the mind. The entire firing mechanism is a simple battery-powered electrical system, and the trigger is the on-off switch. When the trigger is touched the circuit is completed and the electronic primer, which may be compared to a tiny dynamite cap, explodes and ignites the powder charge. Thus lock time becomes the speed of electricity.

This is not a wistful dream. Electronic ignition is already used in military weaponry, and a few years ago a European company introduced electric shotguns and ammo. It is my understanding that a Nevada-based firm will soon begin manufacture of electric shotguns and ammo for trap shooters.

With the need for elaborate and complicated firing mechanisms eliminated, it will be possible to design and manufacture guns that will be stronger, lighter, trimmer, more accurate, more reliable, safer, and cheaper — much cheaper. The cost of electronic primers should be no more than that of conventional primers, possibly less, and cartridge reloading procedures should be virtually the same. Since electronic ignition is vibration-free, a significant cause of accuracy loss in rifles would be eliminated and a major step taken on the road to ultimate accuracy.

Conversion to electronic ignition will, of course, take place over a period of many years. But one factor that will speed up the process is the case with which most existing guns can be converted. I predict that gunsmiths will do a flourishing business converting all types of guns, and that there will be easily installed conversion kits for do-it-yourselfers.

Steel Shot Is Better

It’s interesting to reflect on how our technology has been able to convert “poor substitutes” into products that are infinitely better than the materials they are substituting. This is noticeable in such diverse fields as plastics, medicines, chemicals, textiles, paint, and rubber. Sometimes the reason the substitute is so successful is that the original product was not very good. I think this will soon be the case of steel shot as compared with lead shot.

Just last year a sharp-eyed ballistics engineer happened to notice that one of the energy tables widely used by the shooting industry to determine the relative energy of different sizes of shot at different velocities did not agree with his own calculations. An investigation disclosed that the tables were incorrect and gave a higher than real energy level in all cases. These tables were for lead shot only. The tables for steel shot are of more recent vintage and are correct. But when the two tables are compared, the lead shot energies appear to be a good bit higher than steel than is actually the case. This is causing some red faces among those who have debated the advantage of lead over steel shot, but the debate is a foolish one in any event. The really important error too many of us have made is to assume that lead shot is efficient while steel is not. The truth is that steel pellets are terribly inefficient projectiles and lead pellets are not much better. A few years from now, when we are smacking ducks dead at 80 yards and beyond with steel projectiles, we’ll wonder how we could have ever been satisfied with anything as inefficient as lead shot.

You see, the problem is not with steel or lead shot but with the shape of the pellet. One of the first charges leveled against steel shot was that because of its relative lightness it would be impossible to pack an adequate weight of shot in a standard 12-gauge shell. This has been disproved. But the fact remains that round balls, steel or lead, packed together make the least efficient use of space. It·s because of all that empty wasted space between the spheres.

Of more importance to the shooter is the ballistic inefficiency of a sphere: in other words. its relatively small mass (weight) in relation to its frontal area. Compare this to a modern conical bullet that is three or four times longer than its diameter and has a more streamlined frontal area. Such a projectile loses its velocity slower than a sphere of the same material, and since velocity is the main component of energy it also retains a higher energy level.

So actually, lead versus steel is not and never should have been the issue. The problem is shape. Ballistic shape. For centuries shooters have used round lead shot because it is convenient to make. But round steel shot is not convenient to make that’s why it costs so much. And it may, in fact, be easier and cheaper to make steel into other, ballistically superior shapes. These shapes could be such as to duplicate the ballistics of lead shot. But why stop there? Why not make the substitute better than the original?

Teardrops and Flechettes

There are all sorts of shapes that would work well. One suggested shape is a simple teardrop form. The tail adds weight, keeps the shot in a face-on position in flight, and requires less space per weight unit than true spheres of equal diameter because the tail occupies the otherwise empty space.

But teardrop shot may be difficult to make. A shape that would be easier to make as well as be of superior ballistic efficiency is a fechette or small dart. Pointed on one end with a pressed, arrowlike fletching on the other, the darts fly point-on and thereby lose their velocity and energy less rapidly than a sphere. This means greater punch at longer ranges-ranges we now con sider all but impossible.

Flechettes can be easily and cheaply made because the know-how and machinery already exist. Using equipment similar to that used to make common nails, soft steel wire can be chopped and stamped into flechettes both efficiently and expensively. By using wire that is triangular or hexagonal in cross section, the darts can be packed side by side for an even higher, nearly 100 per cent, loading density.

I envision a shotshell loaded with three layers of darts measuring some three eighths to half an inch each.

Since early tests have shown that the flechettes tend to pattern very tightly, it may be necessary to make them somewhat irregular, or curved, to open patterns a bit. Or perhaps a percentage of the darts can be deliberately loaded backward. Upon exit ing the muzzle, they would turn around in flight and create enough turbulence to open the pattern.

This gives rise to a whole new speculation. If pattern density can be regulated by the shotshell alone, then the need for choke in a shotgun barrel would be eliminated in one brilliant innovation. The hunter could then shoot either quail or geese with the same shotgun simply by using the ammo that gives the desired pattern density. In other words, the mythical, all-purpose shotgun would then at last become a reality.

Range-Finding Scopes

In my book, “The Modern Rifle” (Winchester Press) I postulated a riflescope of the future that would include a laser-type range-finding computer that gives an exact distance reading on any object the crosshairs touch. Though I was only daydreaming, it appears that a similar electronic instrument has been developed for determining distances. If adapted to riflescopes, an additional calculating clement could be installed that instantly computes the bullet drop at the indicated range and automatically adjusts the scope setting. Thus, the scope would constantly and automatically be resetting itself to put the bullet exactly where the crosshairs were aimed.

The military applications of such a sight are obvious, and there may be a few sporting purposes such as some forms of target shooting. But I don’t feel that such a device should be used for the sport hunting of game. However, the technology is here.

A riflescope that does almost the same thing but with the shooter doing the adjustment for range is Redfield’s new Accu-Trac system. Built around a Redfield Widefield 3-9X variable power scope. the Accu-Trac utilizes a range-finding concept that brackets the body profile of a deer between two crosswires seen in the upper part of the scope’s field of view. The magnification adjustment ring is turned until the crosswires touch the back and belly of the deer, and the approximate range is shown on a scale visible in the lower part of the scope’s field of view.

Read Next: Carmichel in Australia: Charged by a Backwater Buffalo

With this information in hand, the hunter then turns an oversize elevation adjustment knob to the corresponding range setting. This is visible in a window in the rear of the adjust ment turret. With the knob thus adjusted. the scope is reset to put the bullet on tarn:et at the indicated range. The whole operation takes only a few seconds. It isn’t a computer, but it 1s definitely a guesswork remover.

Also in the works is an image stabilizer that actually takes the shake and wobble out of your aim. It has already been applied to camera lens and telescopes, so it might just be around the corner for riflescopes.

Read the full article here

![Democrat Party Imploding, Insider Reveals How Bad it Has Gotten [WATCH] Democrat Party Imploding, Insider Reveals How Bad it Has Gotten [WATCH]](https://www.rvmnews.com/wp-content/uploads/2025/07/2025.07.27-12.16-rvmnews-68861881bda28.jpg)

![ICE Agent’s Family in Danger Because Libs Can’t Accept ‘FAFO’ Consequences: Tom Homan [WATCH] ICE Agent’s Family in Danger Because Libs Can’t Accept ‘FAFO’ Consequences: Tom Homan [WATCH]](https://www.lifezette.com/wp-content/uploads/2025/09/2025.09.08-11.03-lifezette-68beb7f4a410d.jpg)

![NBA Coaches Slam ICE After Minneapolis Shooting, Video Tells Different Story [WATCH] NBA Coaches Slam ICE After Minneapolis Shooting, Video Tells Different Story [WATCH]](https://www.drewberquist.com/wp-content/uploads/2026/01/2026.01.11-11.31-drewberquist-696389fddf180.jpg)